Project

Vietnam’s manufacturing revolution: unlocking smart factory potential with ABeam Consulting

Published

11 months agoon

Many manufacturers recognise the need for automation and digital transformation but struggle with the first step. Common questions arise. Where should we start? What impact will it have? How do we secure budget approval? Without clear answers, companies often revert to labour-intensive operations, relying on manual workarounds to sustain production. Even when companies begin digitalisation, they typically focus on isolated improvements, automating a single process or upgrading specific equipment, without a holistic optimisation plan. This leads to limited efficiency gains and prevents businesses from unlocking the full potential of a smart factory.

Additionally, meeting evolving customer demands adds pressure to manufacturing processes. Companies are increasingly tasked with multi-variety, small-lot production and short lead times, all while maintaining high customer satisfaction. These demands create complexities in production environments, increasing the burden on employees and making production management more difficult. As production complexity grows, so does the challenge of transferring critical skills as experienced workers retire, making it harder to modernise operations. Manufacturers also face sustainability pressures, from circular economy compliance to environmental regulations, further complicating digital transformation efforts.

Beyond selecting the right technology, factory leaders often struggle to justify digital investments due to unclear return on investment projections. Without a structured and strategic approach, transformation efforts lack direction, making it difficult to gain leadership approval. This uncertainty can lead to budget rejections, causing companies to continue relying on labour-intensive processes and delaying necessary modernisation.

|

| Yoshihiro Wake |

“A smart factory is no longer a luxury or strategic option, it’s essential to remain competitive in today’s fast-evolving market. Companies that resist embracing automation risk falling behind in meeting customer demands and industry standards,” said Yoshihiro Wake, lead of transglobal expansion frontier at ABeam Consulting Vietnam. The choice is straightforward: take proactive steps to modernise now, or face increasing challenges that could undermine long-term success.

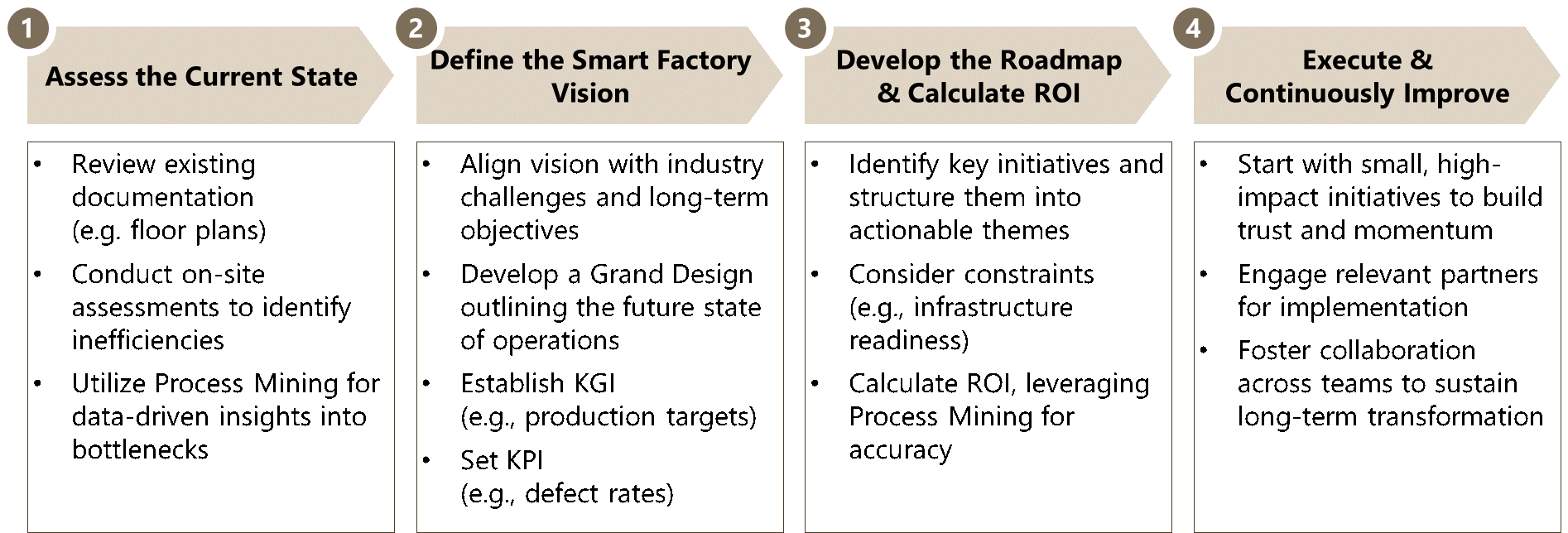

ABeam Consulting’s approach to smart factory transformation is structured to help companies assess their current operations, define a vision for the future, and implement technologies that improve efficiency and productivity.

The first phase of the approach is assessing the current state of operations. ABeam begins by reviewing existing documentation, such as floor plans, production layouts, and work instructions. An on-site assessment helps identify real-world inefficiencies and provides a clear baseline for transformation. Process Mining is one option in this phase, offering data-driven insights into operational inefficiencies by analysing real-time process data. This technology is particularly effective in Vietnam’s manufacturing sector, where companies can gain a more in-depth understanding of process bottlenecks and inefficiencies.

Following the assessment, the next step focuses on defining a clear smart factory vision. This vision should reflect the company’s specific needs, industry challenges, and long-term objectives. ABeam works closely with key stakeholders to build a Grand Design that outlines the desired future state of the factory. It’s essential for the company to establish its key goal indicators (KGI), such as overall production goals, market expansion targets, and operational stability. These goals serve as the foundation for the transformation. Once the KGIs are defined, key performance indicators (KPI) should be set to track progress towards those goals. KPIs might include production efficiency, defect rates, or lead times, providing measurable checkpoints to track success.

|

Once the vision and grand design are established, ABeam Consulting works to create a clear roadmap. This step involves identifying key initiatives aligned with the vision and structuring them into actionable themes. It’s important to account for potential constraints, such as space limitations, infrastructure readiness, or workforce adaptability, which could impact the feasibility of specific initiatives. These constraints are addressed during the transformation process. Additionally, ROI projections are made at this stage. If process mining was used in the assessment, it allows for more accurate ROI calculations, grounded in real-time operational data and visible process bottlenecks. In this context, some may view these initiatives not just as costs, but as investments in growth, positioning the company for long-term success.

With a roadmap in place, ABeam guides companies through the execution phase of transformation. However, the process is not a one-time event but a continuous journey. It’s critical to begin with small, impactful initiatives that yield early wins, building trust and momentum. These initial successes set the stage for ongoing improvements and a continuous cycle of transformation. ABeam supports clients in maintaining momentum by collaborating with the right partners, such as the Internet of Things and AI system vendors, and engaging key stakeholders across the organisation. By fostering collaboration, ABeam ensures that the smart factory journey stays on track and delivers lasting results.

Case study

An apparel manufacturer located in southern Vietnam has adopted a pull-based production model, supported by an automated warehouse system that ensures the timely delivery of parts in response to customer orders, improving the efficiency of the production line. The facility has also advanced its factory automation (FA) initiatives, reducing the need for manual labour in production processes.

Looking ahead, the company envisions leveraging IoT and AI to enable data-driven control and optimisation. The goal is to use accumulated knowledge and established models to make optimal decisions, while driving continuous improvement through an autonomous plan-do-check-act cycle. Another key objective is to develop a local management structure independent of expatriate staff. However, the specific actions required to achieve these goals are still being defined.

In the initial phase of the project, the company aims to:

- Diagnose the current level of smart factory implementation at the facility.

- Identify challenges that hinder the realisation of the desired future state and evaluate potential high-impact, feasible solutions.

- Select proof of concept (PoC) themes that address these challenges effectively.

|

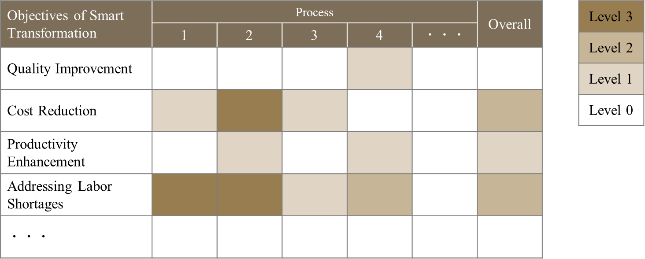

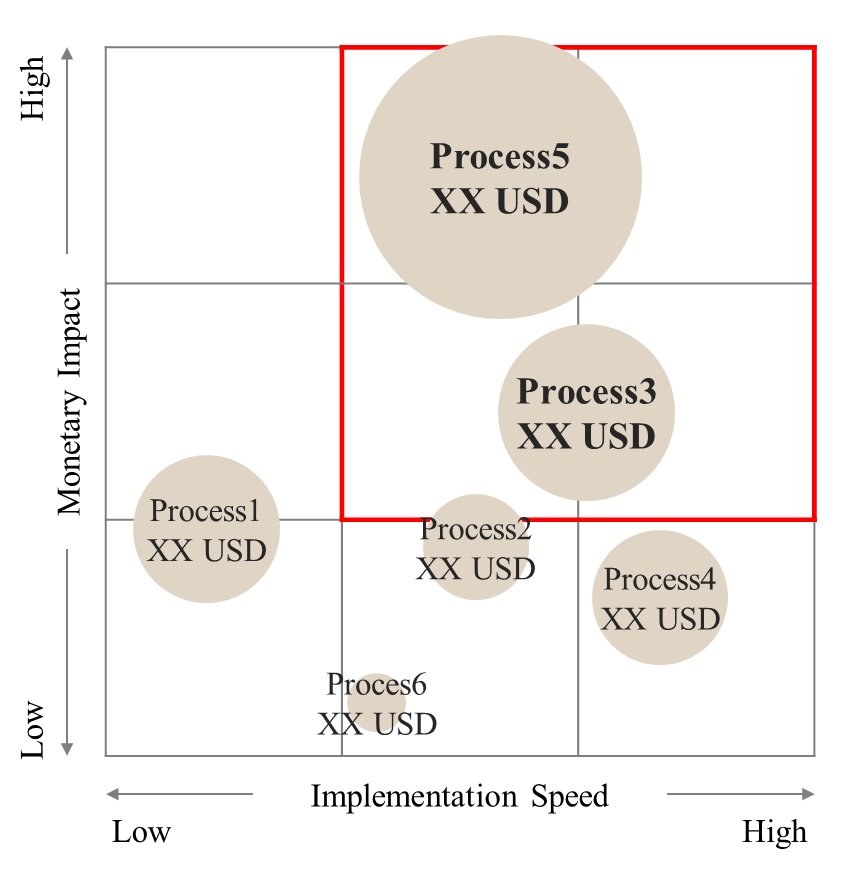

To achieve this, a comprehensive assessment of the current state was conducted, combining smart factory objectives with process evaluations to generate a heat map of performance. This was followed by discussions with key stakeholders to align on the desired future state of the factory and prioritise initiatives. Finally, based on the monetary impact and implementation speed, the most promising PoC themes were selected to drive the transformation forward.

|

This approach provides a strategic roadmap for evolving the factory into a fully integrated smart manufacturing environment, focusing on maximising efficiency, automation, and data-driven decision-making, while maintaining the flexibility to adapt to future needs.

Strategic importance

A smart factory is essential for manufacturers striving to stay competitive in an evolving industrial landscape. By integrating digital technologies, companies can enhance efficiency, reduce costs, improve quality, and future-proof operations against workforce and market challenges.

“When realising a smart factory, it’s crucial to recognise that its ultimate goal varies for each company. Rather than simply following the latest factory trends, businesses must develop a tailored Grand Design that aligns with their specific needs and long-term vision. The transition to a smart factory is not just an upgrade, it is a strategic necessity for sustainable growth and long-term success,” said Yoshihiro Wake.

As Vietnam continues to solidify its position as a global manufacturing hub, companies that embrace smart factory transformation will gain a significant competitive advantage. Looking ahead, the integration of AI, IoT, and data-driven automation will be instrumental in shaping the next generation of manufacturing excellence in Vietnam.

You may like

-

Vietnam’s Exclusive Economic Zone boasts over 1,000 GW of wind power potential: report

-

Uncertainty weighing on real estate

-

Central Vietnam city seeks $1.84 bln for 15 projects in economic zone

-

Green engagement rides high in Vietnam

-

New standards being reached within green industrial parks

-

Vietnam PM asks Warburg Pincus to invest ‘further and faster’

Project

Vietnam’s Exclusive Economic Zone boasts over 1,000 GW of wind power potential: report

Published

10 months agoon

April 27, 2025Vietnam’s Exclusive Economic Zone (EEZ) has a wind power potential of 1,068 GW, nearly 470 GW more than previously estimated, according to a report released Friday by the National Center for Hydro-Meteorological Forecasting (NCHMF).

An offshore wind power project in Vietnam. Photo courtesy of VnEconomy.

The report, titled “Detailed Assessment of Wind Resource Potential in Coastal (up to 6 Nautical Miles) and Offshore Areas in Vietnam,” was conducted by the NCHMF with support from the United Nations Development Program (UNDP) and the Norwegian Embassy.

This wind potential was measured at a height of 100 meters above sea level, said Mai Van Khiem, director of the NCHMF. He noted that from November to February each year, wind capacity accounts for half of the annual total – peaking in December and gradually decreasing, with the lowest levels recorded in May.

The southern offshore areas account for 894 GW of this potential, while the northern areas contribute 174 GW.

In nearshore zones (up to 6 nautical miles), the total technical wind power potential is 57.8 GW. The Bac Lieu-Ca Mau region alone contributes nearly 30% of this, while the Ninh Thuan-Binh Thuan area accounts for 24 GW. Although the Quang Tri-Hue region has lower potential, it offers stable wind speeds during the winter months. The Red River Delta has a modest potential of 0.17 GW.

Compared to previous assessments, such as the World Bank’s 2021 study and data from the Global Wind Atlas (GWA), this report provides more detailed and higher-resolution information, both spatially and temporally.

“Notably, the EEZ potential outlined in this report exceeds the World Bank’s estimate by 469 GW, primarily due to the broader scope of the survey and more refined climate modeling using domestic observational data,” the research team explained.

They also emphasized the use of the Weather Research and Forecasting (WRF) model customized specifically for Vietnam, which enhanced the accuracy of the results.

The findings are based on wind data collected from 26 coastal and island meteorological stations, satellite sources from CCMP, ASCAT, and SCATSAT-1 (covering 30 years of ocean surface wind data), as well as buoy data from Nghe An province and seabed depth measurements.

A key innovation in this report is the integration of potential impacts from extreme weather events. Typhoons and tropical depressions occurring between August and October pose structural and safety risks to wind turbines. Meanwhile, strong winds and high waves during the northeast monsoon season can hinder access to and maintenance of offshore wind systems.

To support model calibration and long-term observation, the research team recommends increased investment in offshore wind monitoring stations at heights exceeding 100 meters. They also suggest incorporating these findings into offshore wind development strategies and national marine spatial planning.

Additionally, the team advocates for expanding research into other forms of marine renewable energy, such as wave, tidal, and ocean thermal energy.

“Vietnam has some of the most promising offshore wind resources in the region, creating a strong foundation for the development of a large-scale offshore wind industry. This will contribute to energy security, green economic growth, and the achievement of net zero commitments,” they said.

The study provides a vital scientific basis for policy planning, identifying priority development zones, attracting investment, building infrastructure, and training the future offshore wind workforce, the team added.

Hoang Duc Cuong, deputy director of the Department of Meteorology and Hydrology, emphasized that Vietnam lies within a strong and stable Asian monsoon belt, giving it abundant wind energy potential. He noted that this renewable source will play a key role in meeting the country’s climate change goals and advancing a low-carbon economy.

However, he also warned that marine-based natural disasters are highly complex and could significantly impact the stability of offshore wind operations and energy generation.

The ever-changing status of the global economy following last week’s tariff shocks continue to loom large among investors in Vietnam’s real estate market.

|

| All real estate segments are at risk of losing appeal if high global tariffs are eventually put in place, photo Le Toan |

Pham Lam, vice chairman of the Vietnam Real Estate Association, said that while it is premature to determine the full impact of new US import tariffs on Vietnam’s property market, early signs point to shaken investor sentiment and potential disruptions to foreign investment.

“If multinational corporations scale back or delay their factory expansion plans, the demand for land and factory leasing could decline, which may place downward pressure on industrial rents, lead to increased vacancy, and postpone new industrial zone developments,” he said. “This would affect key industrial property markets such as Bac Ninh, Bac Giang, Haiphong, Long An, and Binh Duong.”

Meanwhile, real estate expert Nguyen Hoang said that the United States remains one of the most critical export destinations for Vietnam’s foreign-invested enterprises.

“Any change in tariffs will significantly influence capital flows, investor confidence, and manufacturing strategies of companies operating in Vietnam. If a high tariff is fully implemented in 90 days, it could seriously diminish Vietnam’s investment appeal – affecting all real estate segments as a result,” Hoang said.

Vietnam’s property market has only recently emerged from a prolonged two-year downturn.

“It remains highly sensitive to economic and policy shocks. Investors have remained cautious, and any further external pressure could threaten to break the fragile liquidity recovery, potentially sending the market back into a period of short-term stagnation,” Hoang added.

Alex Crane, managing director of Knight Frank Vietnam, said that the recent tariff twists by the US casts a shadow of uncertainty, with potential implications for various segments of the market.

While manufacturing has shown resilience, it is still on the path to full recovery from the pandemic, particularly in labour-intensive sectors like garments and furniture. Tariffs imposed now would not have as severe an impact as they might have during Vietnam’s 2019 peak, but consequences are still expected, Crane said.

“I may expect that major transactions, especially those involving large capital outlays, are being paused or undergoing extended due diligence as investors and developers reassess assumptions and underwriting models and commercial occupiers are expected to defer large capital expenditures in the short term,” Crane said.

In addition, the response from the State Bank of Vietnam, particularly regarding monetary policy, will be crucial. While a rate cut may not effectively stimulate residential demand (as demonstrated in 2024), targeted lending for key industries and easing of loan-to-value ratios or debt-to-income limits for developers could provide relief.

“At present, most segments of the real estate market are in a holding pattern, awaiting clarity from the evolving negotiations between the Vietnamese and US governments. While uncertainty is unsettling, Vietnam’s underlying fundamentals remain sound, and the market’s long-term outlook is still viewed positively,” he added.

Nguyen Dung Minh, deputy CEO of MIK Group, has warned that under the new US tariff regime, many investors will be forced to reassess their strategies, likely leading to a decline in the demand for industrial land.

“Investors will need time to re-evaluate their actual demand and incoming orders and make necessary adjustments before they can fully gauge the extent of the impact,” Minh said.

He added that the implications go beyond just industrial land. “The new US tariffs are also expected to disrupt supply chains and negatively affect supporting sectors such as logistics, warehousing, and raw materials manufacturing. As production slows, so too will the demand for land associated with these services,” Minh said.

| Trang Bui, country head Cushman & Wakefield Vietnam

While the effects of tariffs are typically delayed, most economists warn that they may eventually fuel inflation and dampen economic growth. Many manufacturing firms could opt to postpone their expansion plans in the short term if export duties become too burdensome. There is also a possibility that some companies may look to diversify their supply chains towards a Vietnam+1 model, shifting parts of their operations to neighbouring countries. This could lead to a decline in demand for factories and warehouse leasing, two key drivers of the industrial real estate segment. However, it is important to recognise that industrial real estate is fundamentally a long-term investment. Vietnam has long positioned itself as the manufacturing hub of Southeast Asia, thanks to its strategic location and the “bamboo diplomacy” approach, which has enabled the country to swiftly join trade negotiations and sign multiple free trade agreements. Moreover, many manufacturers in Vietnam have already established tightly integrated supply chains. As such, their investment plans tend to operate on a much longer time horizon than the near-term effects of tariff policy. Relocating supply chains typically requires at least 3–5 years, making short-term shifts less likely. Overall, Vietnam’s industrial real estate sector has proven resilient under various political and economic conditions. Investors would do well to focus on long-term trends and structural advantages. Manufacturers, in particular, may take this opportunity to secure high-quality industrial assets, invest in automation, and pull in skilled labour, while continuing to monitor developments in upcoming trade negotiations with caution. Nguyen Thi Bich Ngoc, CEO, Sen Vang Group When it comes to the reciprocal tariff policy announced by the US, the greater danger currently lies not in the tariff itself, but in the heightened sense of uncertainty it has triggered across the Vietnamese market, a sentiment clearly reflected in recent VN-Index fluctuations. In the short term, the policy will weigh heavily on Vietnam’s industrial real estate sector. However, in the long run, this challenge could serve as a catalyst for stronger growth. It presents an opportunity for the government and industrial zone developers to rethink their strategies, offering more competitive, attractive solutions to both foreign and domestic investors. Rather than relying solely on external trends like the China+1 shift, Vietnam should leverage its inherent competitive advantages, including a strategic geographic location, a skilled and cost-effective labour force, and political stability, to pull in long-term investment. These are undeniable strengths that set Vietnam apart. Moreover, this is also an opportune moment for Vietnam to re-evaluate and restructure its key sectors, prioritising strategic industries with high growth potential. Continued engagement in bilateral and multilateral trade agreements will open up new opportunities and elevate Vietnam’s position both regionally and globally. Ultimately, we must seize this challenge as a turning point, transforming pressure into momentum for sustainable development. Vo Hong Thang, Investment director DKRA Group The industrial infrastructure, commercial, and residential real estate segments are all likely to face increasing headwinds if a huge tariff increase is eventually implemented. In recent years, a number of developers have made significant investments in industrial zones, betting on a continued influx of foreign direct investment. However, the new tariff policy raises the possibility of such flows being diverted to other countries. Vietnam now faces the risk of having built the nest, but being unable to attract the eagle. In addition, liquidity in both residential and commercial real estate, including retail, office, and hospitality, is likely to weaken in the short term due to more cautious investor sentiment, defensive capital flows, and reduced purchasing power from end-users. Niche investment segments such as serviced apartments, tourism-related accommodations, and foreign buyer housing could also see demand drop, particularly as the foreign expert and executive workforce, typically a key demand driver, scales back plans to live and work in Vietnam. |

Project

Central Vietnam city seeks $1.84 bln for 15 projects in economic zone

Published

10 months agoon

April 26, 2025Authorities of Hue city in central Vietnam have released a list of 15 projects in Chan May-Lang Co Economic Zone which will need VND47.5 trillion ($1.84 billion) in investment capital between 2025 and 2026.

Chan May-Lang Co Economic Zone in Hue city, central Vietnam. Photo by The Investor/Dinh Duy.

Notable projects include the Chan May non-tariff zones No. 1 and 2 infrastructure development project, with a total area of over 503 hectares and combined investment capital of VND2.8 trillion ($108.23 million).

Another is the VND20 trillion ($773 million) Chan May Urban Area project (locations 1 and 2), which will cover 225 hectares and be implemented over five years.

The LNG terminal project at Chan May Port, 27 hectares with an investment of VND8.6 trillion ($332.43 million), is set for five-year implementation.

The 120-hectare Bai Ca eco-tourism project in Lang Co township will have investment capital of VND2.5 trillion.

The Lang Co beach resort, with an area of 45 hectares and total investment of VND4 trillion ($154.62 million), will be carried out over five years; while the 75-hectare Lap An lagoon tourism, urban development and resort complex in Lang Co township will cost VND6 trillion.

According to the management board of Hue Economic and Industrial Zones, since its establishment, Chan May-Lang Co Economic Zone has attracted 55 investment projects which remain valid, with total registered capital of VND97.32 trillion ($3.76 billion).

Among these, 15 are foreign-invested projects with combined capital of VND56.02 trillion ($2.17 billion), accounting for 57.56% of the total.

Several prominent foreign investors have established a presence in the zone, such as Banyan Tree Group (Singapore) with the Laguna Lang Co Resort and Winson Group (Taiwan) with the Billion Max Vietnam Export Processing Factory.

Chan May-Lang Co has become a destination for investments in sectors like tourism and resort development; seaport infrastructure; logistics; clean industry; and high-tech, environmentally friendly industries, with annual revenue reaching nearly VND4 trillion ($154.62 million) and tax contributions of around VND300 billion.

The management board said Hue city has proposed the Ministry of Construction review the adjustment of the EZ master plan through 2045, for submission to the Prime Minister.

The strategic goal is to develop Chan May-Lang Co into a key economic zone of central Vietnam – a coastal gateway offering logistics services for the central region and the East-West Economic Corridor, as well as a hub for high-end tourism services.

To attract investors, the local government will offer a range of incentives such as a 10% corporate income tax rate for 15 years from the first year the project generates revenue; import tax exemption for goods to create fixed assets for investment projects, and land and water surface rental exemptions, the board said.

Bac Giang International Logistics Centre launched

Vietnam’s Exclusive Economic Zone boasts over 1,000 GW of wind power potential: report

Uncertainty weighing on real estate

Central Vietnam city seeks $1.84 bln for 15 projects in economic zone