Investing

ASEAN compelled to become microchip hub

Published

11 months agoon

A call has been made for ASEAN member states to develop the region into a vast semiconductor hub, leveraging their strengths in manufacturing chips.

|

| Singapore, Indonesia, Vietnam, and others all boast stronger policies for chip-related manufacturing, photo Le Toan |

During the ASEAN Future Forum 2025 held in Hanoi late last month, Malaysian Prime Minister Anwar bin Ibrahim stated that member states need to cement cooperation in manufacturing semiconductors to turn Southeast Asia into a major hub for such products.

“Malaysia is leading the region in semiconductor manufacturing and the country’s leaders fully support the development of this industry,” PM Ibrahim told Vietnamese counterpart Pham Minh Chinh.

Malaysia began to develop semiconductor products about 20 years ago, with the participation of high-tech investors from the US, China, South Korea, and Japan. This success needs to be shared among other ASEAN nations, according to PM Ibrahim.

Malaysia is the world’s sixth-largest exporter of semiconductors, accounting for 13 per cent of the global assembly, testing and packaging market. It aims to lure in $115 billion worth of investments by 2030.

Last week, British chip company Arm Holdings inked a deal with Malaysia to bolster its efforts to produce high-end semiconductors. The deal will see Softbank-owned Arm provide chip designs and other technology, helping Malaysia to move into more value-added production such as wafer fabrication and integrated circuit design. Malaysia reported to be paying $250 million over a decade to receive support from Arm Holdings.

Malaysia’s national semiconductor strategy aims to invest over $100 billion in advanced technologies. In May 2024, the Malaysian government committed to invest at least $5.6 billion in the semiconductor industry, with the goal of being self-sufficient in chip manufacturing within the next 5–10 years.

“Indonesia, Vietnam, and Thailand also want to develop semiconductors, so all of us need to stay united and boost cooperation in this industry. Malaysia stands ready to support Vietnam in this endeavour,” PM Ibrahim said.

The global semiconductor industry is undergoing a significant transformation, with ASEAN emerging as a prominent player. Geopolitical tensions have opened opportunities for the region, with key contributors like Singapore and Malaysia leading the way.

ASEAN, in its effort to diversify the global supply chain, has recorded impressive growth. Total semiconductor exports from the region reached $268.8 billion in 2023, accounting for almost one-quarter of the global market. A 41.6 per cent increase in exports from 2018 to 2023 underscores the industry’s growth in this area.

Vietnam’s semiconductor industry is led by strategic government policies, raising foreign investment, and a growing demand for chips in various industries. With a projected market value of $31.28 billion by 2027 and a compound annual growth rate of 11.6 per cent from 2023 to 2027, Vietnam is steadily positioning itself as a key player in the global semiconductor supply chain, according to Dezan Shira & Associates.

After Vietnam and the US forged a comprehensive strategic partnership in 2023, the former’s semiconductor industry has been beefed up, with larger participation from global semiconductor giants such as Intel, OnSemi, Hana Micron, and Amkor. They are particularly found in outsourced semiconductor assembly and test (OSAT) facilities in the northern region, and research and development centres in the south.

Under Vietnam’s semiconductor strategy towards 2030, with a vision extending to 2050, the country will centre on talent development, manufacturing capacity, and global integration. According to the strategy, the country will establish at least 100 design companies, one small-scale manufacturing facility, and 10 packaging and testing plants, with annual revenue in the semiconductor industry of $25 billion, all by the end of this decade.

Those revenues will aimed to be doubled by 2024 and, from there to mid-century doubled again to $100 billion, with Vietnam seeking to boast 300 design companies, three fabrication plants, and 20 OSAT plants.

However, experts said a lack of high-quality personnel, underdeveloped infrastructure, and administrative hurdles need to be addressed.

Other ASEAN countries, such as Indonesia and Singapore, are also ramping up efforts.

Singapore is expanding its wafer fabrication zones and enhancing business support services. According to Singapore’s Economic Development Board, over the past decades, Singapore has become a semiconductor powerhouse, holding 10 per cent of the global chip production and about a fifth of the world’s chip-making gear.

Singaporean Prime Minister Lawrence Wong in his budget speech late last month said that Singapore has attracted global AI and quantum computing firms. He pledged to spend around SGD1 billion ($747 million) on a new chip research facility.

Singapore already houses plants for blue-chip US manufacturers including memory chip specialist Micron, outsource manufacturer GlobalFoundries and fabrication-equipment supplier Applied Materials.

Meanwhile, Indonesia, with its abundant raw materials, is developing a supply chain from raw material extraction to production. This regional competition not only elevates ASEAN’s position in the global semiconductor market but also fosters collaboration to create an integrated value chain.

“To strongly develop the semiconductor industry successfully, we need to pay special attention to training high-quality personnel,” Malaysian PM Ibrahim said.

Vietnam is aiming to train 50,000 skilled engineers for the industry by 2030 and about 100,000 by 2040.

You may like

-

Amkor urged to expand advanced chip packaging in Vietnam

-

Danang lights the way in building chip/AI ecosystem

-

Investment required to exploit AI potential

-

Ministry of Finance to encourage AI and semiconductor R&D

-

AISC 2025: Vietnam’s new role in AI and semiconductors

-

Amkor Technology seeks approval for importing used machinery

Investing

Bac Giang International Logistics Centre launched

Published

9 months agoon

April 27, 2025Bac Giang International Logistics Centre was launched on April 22 with an investment of $168 million, and is expected to become a crucial link in the global supply chain.

|

| Bac Giang International Logistics Centre launch |

Being invested by CNCTech Group, Dolphin Sea Air Services Corporation and Thien An Investment JSC, the logistics centre is located on National Highway 1A, which boasts first-class warehouse supply to meet the growing demand in the northern Vietnamese market.

Its strategic position within the golden economic triangle of Hanoi – Haiphong – Quang Ninh provides convenient connectivity to industrial zones and key logistics centres via national highways No.1A and No.37.

The centre is designed to meet growing demand for logistics infrastructure from businesses in Bac Giang and neighbouring provinces, positioning the area as a new node in northern Vietnam’s logistics network.

The project is a strategic product as a key component of the logistics spearhead in CNCTech Group’s industrial and logistics infrastructure ecosystem. It has been approved by the prime minister as a national level-II logistics centre, covering a planned area of 67 hectares.

At the launch ceremony, Chairman of Bac Giang People’s Committee Nguyen Viet Oanh said, “In recent years, the province’s socioeconomic development has made remarkable strides. Transportation, urban, industrial, and social infrastructure have been synchronously invested in and have yielded high efficiency. However, the province’s logistics service sector has not yet matched its potential, advantages, and socioeconomic development level. The logistics system remains fragmented, transportation costs are high, and trade delivery times are prolonged.”

Recognising this bottleneck, the local authorities have focused on directing the robust development of the logistics system, incorporating it into the provincial plan. This includes developing eight comprehensive logistics centres covering nearly 500ha, three inland container depots, and 33 inland waterway ports.

“Bac Giang, with its strategic location between Hanoi and border provinces, has long been known as a dynamic industrial hub. The remarkable development of the province’s industrial parks has created a solid foundation for the establishment of Bac Giang International Logistics Centre. This centre is not only located on vital transportation routes such as Hanoi-Lang Son Expressway but also directly connects to major border gates, optimising the transport of goods from Bac Giang to the world,” said Oanh.

|

| A model of the logistics centre |

The project is not merely a warehousing facility, but also a symbol of the integration of modern infrastructure and advanced technology. The centre includes multifunctional warehouse areas, customs-controlled warehouses, non-tariff warehouses, and automated warehouses, meeting the needs of various industries. Notably, it integrates end-to-end logistics solutions, supporting businesses in optimising transportation costs and enhancing production efficiency.

With a long-term vision, the centre aims not only to optimise domestic supply chains but also to become a key connection point in the global logistics network.

Nguyen Van Hung, chairman of the Board of Members of CNC Tech Group, shared, “The establishment of this centre is a strategic step in developing Vietnam’s logistics infrastructure. We are committed to long-term and robust investment in this sector, as logistics is not just infrastructure but an indispensable part of enhancing the competitiveness of Vietnamese businesses on the international stage.”

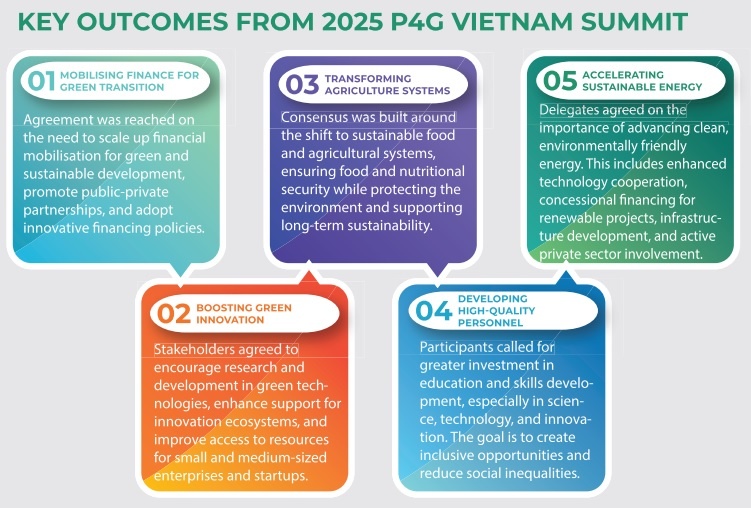

Vietnam has taken strong action to promote green development among businesses, amid the country facing challenges in finance and technology.

Vietnamese Party General Secretary To Lam told the fourth Summit of the Partnering for Green Growth and the Global Goals 2030 (P4G), organised last week in Hanoi, that Vietnam is focused on strategic breakthroughs to prepare for a national development process that is fast, inclusive, and sustainable.

|

| The summit in Hanoi covered areas from finance and banking to agriculture and technology Photo: Dung Minh |

“We will strongly transform political commitments into practical actions, creating motivation for businesses and the whole society to participate in sustainable economic development, in which green institutions are the decisive foundation,” General Secretary Lam stressed at a hall attended by government leaders, UN representatives, diplomats, experts, and entrepreneurs.

General Secretary Lam also stressed that when it comes to green transformation, despite being a developing country with a transitional economy and limited resources, Vietnam has achieved some important results.

Besides making a 2050 net-zero commitment in 2021, Vietnam also endorsed six global initiatives at the time, on forest and land use, methane, clean power transition, sustainable food and agriculture, and more.

“Vietnam is now a leading country in supplying renewable energy in ASEAN, with wind and solar power capacity accounting for two-thirds of ASEAN’s total capacity,” he said.

“Additionally, Vietnam is also a good example of encouraging sustainable agriculture. The initiative to develop one million hectares of high-quality and low-emission specialised rice is a pioneering model that many partners and international organisations are interested in.”

A greener future

Vietnam is an active and responsible member of all multilateral mechanisms and major initiatives on green growth and energy transition such as the Paris Agreement on climate change, the Just Energy Transition Partnership, and the P4G.

“However, as a developing country with a transitional economy, we also face many challenges in terms of financial resources, technology, personnel, and resilience to the impacts of climate change and geopolitical fluctuations globally,” said General Secretary Lam.

The summit adopted the Hanoi Declaration, strongly affirming commitments to sustainable growth with people at the centre, and a determination to collaborate responsibly in addressing current global challenges. Vietnam is expected to enjoy continued support from the international community in its journey to a green economy including energy transition.

According to the World Bank, to ensure sufficient funding for responding to climate change, mobilising domestic finance is possible, but external support is needed.

Overall, Vietnam’s total incremental financing needs for the resilient and decarbonising pathways could reach $368 billion over 2022–2040, or approximately 6.8 per cent of GDP per year.

The resilient pathway alone will account for about two-thirds of this amount, as substantial financing will be required to protect the country’s assets and infrastructure as well as vulnerable people.

The cost of the decarbonising pathway will mainly arise from the energy sector – investments in renewables and managing the transition away from coal might cost around $64 billion between 2022 and 2040. All the figures are in net present value terms at a discount rate of 6 per cent.

This $368 billion in financing needs will include $184 billion from private investments or about 3.4 per cent of GDP annually, $130 billion or about 2.4 per cent of GDP annually from the state budget; and $54 billion or about 1 per cent of GDP per year from external sources.

Choi Youngsam, South Korean Ambassador to Vietnam, said that within the P4G framework, South Korea and Vietnam have completed or are currently implementing joint projects in areas such as food and agriculture, energy, water, and urban development.

“Looking ahead, both sides are expected to broaden and deepen their partnership under the P4G framework,” he said.

At the P4G Summit held in Seoul in May 2021, the two governments signed the Framework Agreement on Cooperation in Response to Climate Change, laying a solid policy foundation for the implementation of international emissions reduction ventures.

“On this basis, I hope that South Korea will leverage its technological expertise and financial resources to carry out greenhouse gas emission reduction projects in Vietnam, with both countries mutually recognising the results,” Ambassador Youngsam said.

“This would contribute to establishing a win-win model of emissions reduction cooperation. At the same time, I look forward to seeing active engagement from South Korean enterprises possessing green technologies, in close collaboration with the Vietnamese government.”

Encouraging developments

Deputy Minister of Science and Technology Hoang Minh said at a policy dialogue on the sidelines of the P4G 2025 that the active participation and strong cooperation from stakeholders – from the public and private sectors to international organisations – can help materialise Vietnam’s aspiration of an efficient and sustainable innovative startup ecosystem.

“Innovation, creative entrepreneurship and collaboration are key to solving environmental problems, while encouraging the development of a circular economy,” he said.

Vietnam currently has over 4,000 innovative startups, including two unicorns valued at over $1 billion, 11 companies valued at over $100 million, more than 1,400 startup support organisations, 202 co-working spaces, 208 investment funds, and 35 business promotion organisations. Among these, it is estimated that around 200–300 companies focus on green transition, covering areas such as renewable energy, environmental technology, sustainable agriculture, and the circular economy.

According to the Vietnamese Ministry of Foreign Affairs, hosting the fourth P4G Conference is of great significance to Vietnam. It is aimed to boost its role as a good friend, a reliable partner, and a responsible member of P4G and the international community. Moreover, it is also aimed to reaffirm its commitment to sustainable development, energy transition, and the goal of carbon neutrality by 2050. Besides that, it is aimed at contributing to raising awareness of international cooperation and encouraging the role and voice of developing countries in the sector of green growth and sustainable development.

| Pham Minh Chinh, Prime Minister

For Vietnam, together with digital transformation, we identify green transition as an objective necessity, a key factor, and a breakthrough driving force to promote rapid growth and sustainable development. This aligns with the strategic goal of becoming a developing country with modern industry and upper-middle income by 2030, and a developed, high-income country by 2045, while also contributing to the gradual realisation of Vietnam’s commitment at COP26 to achieve net-zero emissions by 2050. From practical experience with initial positive results, especially in renewable energy, green agricultural development, and participation in multilateral mechanisms and initiatives on green transformation, as the host of the fourth P4G Summit, Vietnam has three suggestions for discussions which pave the way for further cooperation in the coming time. First is to perfect green mindset, with a focus placed on the development of science and technology, innovation, and digital transformation linked to green growth. This includes recognising that green resources stem from green thinking, green growth is driven by green transition, and green resources arises from the green awareness of people and businesses in nations and regions throughout the world. Second is to build a responsible green community, in which, the government plays a guiding role, encouraging, and ensuring a stable and favourable institutional environment for green growth. The private sector functions as a core investor into technological development and the dissemination of green standards. The scientific community take the lead in developing green technologies and training green human resources. Meanwhile, citizens continuously enhance their green awareness, truly becoming beneficiaries of the outcomes of green transformation. Thirdly, it is necessary to promote international cooperation and robust multilateral green cooperation models, particularly public-private partnerships, South-South cooperation, North-South cooperation, and multilateral cooperation frameworks. This is aimed at removing institutional barriers, enhancing access, and speeding up the flow of green capital, green technology, and green governance. Developed countries should take the lead in fulfilling commitments to provide financial, technological, and institutional reform support. Meanwhile, developing countries would need to leverage their internal strengths and effectively utilise external resources. |

Investing

Public-private partnerships a lever for greener innovation

Published

9 months agoon

April 26, 2025Public-private partnerships are no longer a supporting mechanism, but a strategic pillar in the global pursuit of the green transition.

The high-level dialogue between government leaders and businesses at the 2025 P4G Vietnam Summit last week, chaired by Prime Minister Pham Minh Chinh, brought together senior officials, global experts, international organisations, and private sector leaders.

They recognised that the climate crisis, digital transformation, and resource depletion are converging in ways that demand not only innovation, but deep and long-term collaboration between the public and private sectors.

UN Deputy Secretary-General Amina J. Mohammed acknowledged Vietnam’s leadership in renewable energy, noting its potential to attract trillions in sustainable investment.

“Emerging economies must accelerate the adoption of new investment models, particularly those that align private capital with green infrastructure priorities. Governments must work with the private sector to expand ambition, strengthen accountability, and deliver real impact,” she said.

From Italy, Prime Minister’s Climate Envoy Francesco Corvaro stressed that public-private partnerships (PPPs) are indispensable in addressing climate finance gaps. Drawing from Italy’s experience, he underscored the importance of public investment as a risk mitigator, enabling private sector participation in clean energy and smart infrastructure projects.

“Public investment can unlock private capital, but local authorities must lead with clear priorities and long-term vision,” Corvaro noted. “You can’t talk about renewables, AI, or digital infrastructure without modern, resilient grids, and that requires strong public-private alignment.” he said

Alejandro Dorado, Spain’s High Commissioner for Circular Economy, argued that the case for stronger PPPs lies at the intersection of two accelerating forces: the environmental-climate crisis and a wave of disruptive technologies.

“In a world where AI, green technologies, and digitalisation are reshaping the global economy, the clock is ticking. According to the Intergovernmental Panel on Climate Change, we have less than a decade to prevent irreversible climate disaster. Meanwhile, the World Economic Forum has identified biodiversity loss as one of the most severe economic risks,” he said.

|

Dorado added that while multilateralism is being questioned or weakened in some quarters, the need for cooperation has never been more urgent – both to solve environmental challenges and to harness the transformative potential of innovation.

“No government or business can tackle these crises alone. Public authorities must provide the regulatory frameworks, fiscal incentives, and infrastructure deployment needed at scale to safeguard the common good,” he stressed.

From the business side, Stuart Livesey, country representative of Copenhagen Infrastructure Partners (CIP), provided a frank but optimistic outlook. Livesey stated CIP’s commitment to supporting Vietnam’s transition, but emphasised the need for enabling conditions.

“What we seek are clear, bankable projects underpinned by stable regulatory frameworks, collaborating with strong local partnerships. This is where public-private cooperation becomes not just helpful, but essential,” Livesey noted. “Over the next 10-15 years, the offshore wind sector and green energy consumers will trigger massive demand for new technologies, digital solutions, and skilled labour.”

To meet this demand, CIP is investing not only in infrastructure, but also in capacity building, research and development, and local supply chain development through partnerships with Vietnamese universities.

Still, he acknowledged barriers. “Technological application and innovation in green projects face challenges, from long-term financing constraints and skilled labour shortages to fragmented policy signals. These are not unique to Vietnam, but they require proactive, tailored local solutions,” he said. “Addressing issues such as grid availability, regulatory clarity, and inter-ministerial coordination will be critical.”

Tim Evans, CEO of HSBC Vietnam, stated that the banking sector is ready to facilitate green finance, particularly in sectors aligned with national climate targets.

“We see ourselves as a bridge between global capital and local sustainability goals. The clearer the pipeline of bankable, climate-aligned projects, the faster we can move capital,” he noted. “What’s crucial now is consistency in policy and coordination among stakeholders to ensure these projects reach maturity.”

Bac Giang International Logistics Centre launched

Vietnam’s Exclusive Economic Zone boasts over 1,000 GW of wind power potential: report

Uncertainty weighing on real estate

Central Vietnam city seeks $1.84 bln for 15 projects in economic zone